Wine making today is a combination of centuries old tradition and modern technology. Contaminants including particulates, yeast, crystals and bacteria can adversely affect wine’s quality. Microfiltration is widely used in wine production to remove these contaminants. Art and science are blended to achieve a wine’s unique characteristics, while maintaining uniformity in quality, taste and appearance.

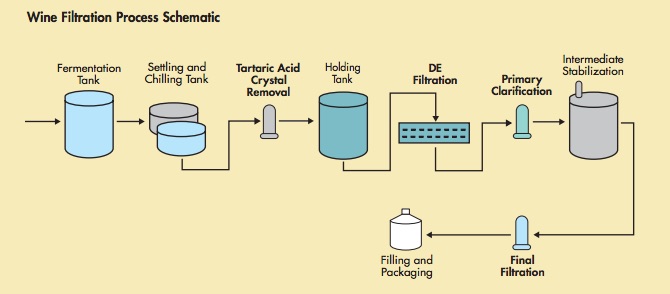

The key role of filtration in wine-making is to provide stabilization. Physical stabilization prevents the formation of hazes and deposits after packaging, while microbiological stabilization eliminates yeasts and bacteria that can destroy a wine’s taste. Filtering out the contaminants that adversely affect stabilization occurs in primary, intermediate and final (terminal) filtration steps.

Tartaric Acid Crystal Filtration

When fermented wine is chilled, colloids and crystals of tartaric acid are precipitated. A melt blown depth filter such as Graver Technologies’ MBF or COAX, or a pleated polypropylene depth filter such as the PMC can be used for initial clarification and crystal removal. This initial coarse filtration step improves the efficiency of downstream processes.

Primary Clarification

Filters such as Graver Technologies’ QMC, QMA, PMA, PMC and GFC are used to remove solids and yeast from fermentation. The primary clarification step also protects the more critical downstream final filters. By offering a wide range of polypropylene and microfiberglass prefilters Graver can optimize the overall filtration process to minimize cost and maximize filter life.

Intermediate Stabilization

During storage or transport, there are two sources of concern over maintaining a wine’s characteristics. The first is the potential for ongoing fermentation, creating additional yeast which can be removed prior to packaging. The second source is the ingress of extraneous contam-inants, either from blanketing gases or through tank vents. Additionally, carbonation gas impurities can negatively affect the consistency of sparkling wines. The TefTEC filter effectively sterilizes gases and removes sub-micron contam-inants. The same filter can act as an effective tank vent. Like all Graver Technologies membrane filters, TefTEC is 100% integrity tested in production.

Final Filtration

Any residual microorganisms that can cause spoilage are removed by final membrane filters. Graver Technologies filters have been validated for the removal of organisms such as Dekkera intermedia, Lactobacillus brevis, and Leuconostoc oenos. The ZTEC-B (beverage grade) filter provides outstanding flow rates and long life, while the backflushable (cleanable and re-usable) VTEC incorporates track etched membrane to provide the industry’s most exact cut-off for results unmatched in consistency.

Water Filtration

As the most widely used component in wine production, water must meet various standards of purity. Quality requirements range from coarse filtration for general use water, to sterilizing filtration for water used in blending and bottle washing. Graver Technologies wide range of prefilters allows optimization of general use water filtration systems, while its absolute-rated membrane filters produce ultra-pure water for critical applications.

Filtration of Organisms in Wine Making

Filtration is used to microbially stabilize wine by removing, or controlling the proliferation of foreign and cultured organisms. Wine’s alcohol constituent is produced during fermentation when yeast (Saccharomyces cerevisiae) converts sugars into ethanol and carbon dioxide. Wine’s acidity can be manipulated by lactic acid bacteria (Leuconostoc oenus). Ironically, these organisms used to give wine its unique charac-teristics can lead to undesirable tastes and aromas. Wine stored in bulk tanks can become spoiled by species of Dekkera and Saccharomyces ludwigii, and film-forming yeasts such as Issatchenkia orientalis, Pichia membranaefaciens and Candia spoil wines stored in barrels.

In extensive laboratory testing the QMC developed by Graver Technologies has been tested to prove its reliable removal of larger organisms, while the VTEC and ZTEC-B filters have been validated for the removal of various bacteria and yeast.

All information and recommendations appearing in this bulletin concerning the use of products described herein are based on tests believed to be reliable. However, it is the user’s responsibility to determine the suitability for his own use of such products. Since the actual use by others is beyond our control, no guarantee, expressed or implied, is made by Graver Technologies as to the effects of such use or the results to be obtained. Graver Technologies assumes no liability arising out of the use by others of such products. Nor is the information herein to be construed as absolutely complete, since additional information may be necessary or desirable when particular or exceptional conditions or circumstances exist or because of applicable laws or government regulations. MBF, COAX, QMA, PMA, PMC, GFC, TefTEC, QMC, ZTEC-B, VTEC and QCR are trademarks of Graver Technologies.

This technical brief was supplied by Graver Technologies. Browse our Graver product offering online here.

Updated